| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : Zhonghe Machinery

Model Number : VH009

Certification : CE, patent, ISO

Place of Origin : China

MOQ : 1 set / piece

Price : USD 199.00-USD9999.00

Payment Terms : T/T, L/C

Supply Ability : 5 sets per week

Delivery Time : 5-25/works

Packaging Details : bubble / wooden cases

Material : High Strength

Shock-absorbing rubber : Imported from South Korea

Quality : High Quality

Motor : Parker motor

Bearings : SKF's VA405 bearings

Clamping cylinder : Largest diameter

Zhonghe Machinery's Vibration Hammer Work High Efficiency

Introduction of Zhonghe Machinery's Vibration Hammer:

In today's fast-paced industrial landscape, efficiency and precision are paramount. Zhonghe Machinery has emerged as a leader in innovative construction equipment, and its Vibration Hammer exemplifies this commitment to excellence. Designed to enhance productivity in various applications, the Vibration Hammer combines advanced technology with robust engineering to deliver unparalleled performance.

This introductory overview explores the key features and benefits of Zhonghe Machinery's Vibration Hammer, highlighting its versatility in soil compaction, foundation construction, and other essential tasks. As we delve into the specifications and applications of this cutting-edge tool, it becomes evident how Zhonghe Machinery continues to set new standards in the machinery industry. Whether for small-scale projects or large construction sites, the Vibration Hammer is engineered to meet the demands of modern construction with reliability and efficiency.

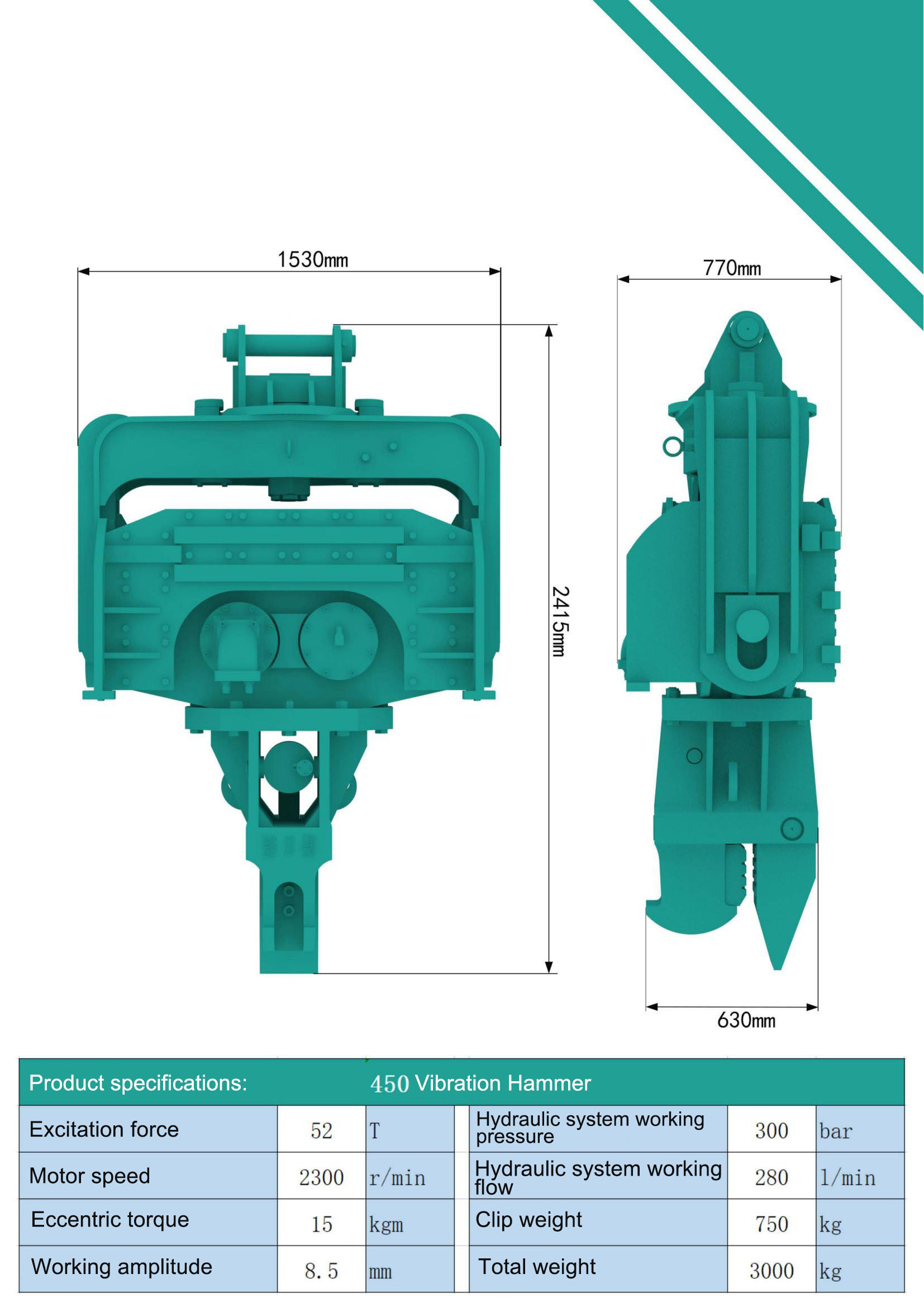

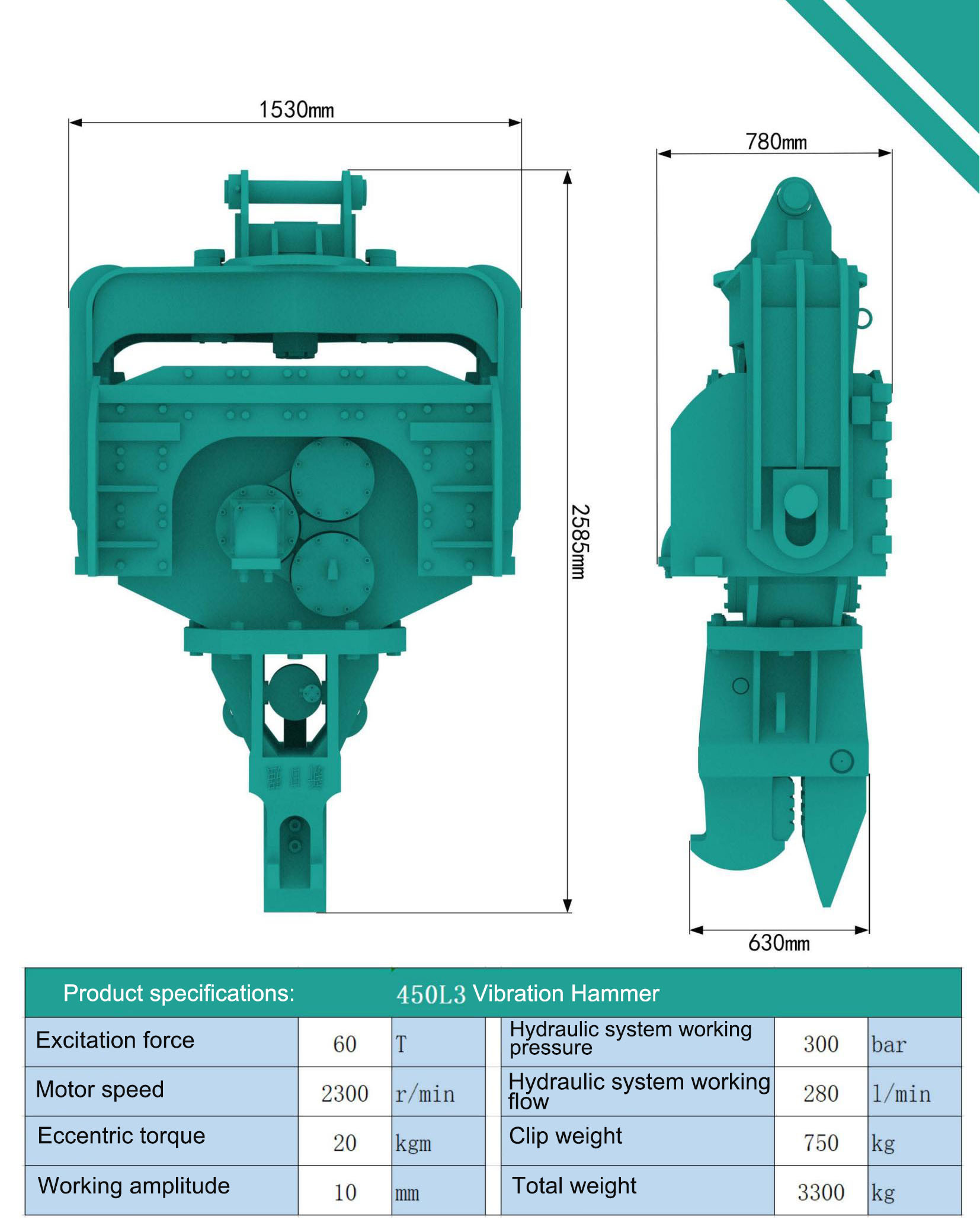

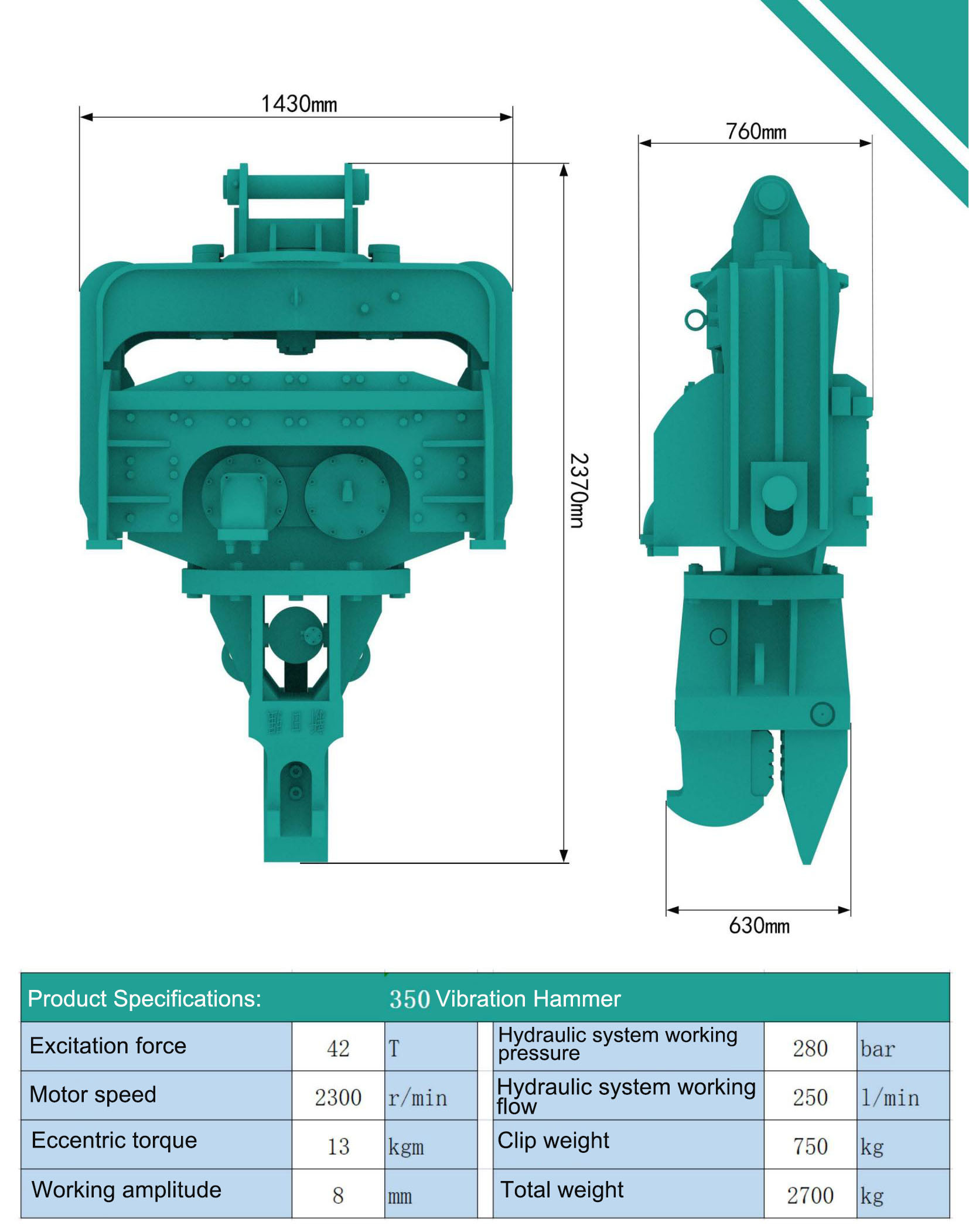

Specifications of Zhonghe Machinery's Vibration Hammer:

Key word: Excavator Vibratory Pile Driver, Excavator Hammer, Excavator Vibration Hammer.

Production Details of one set of Excavator Vibratory Pile Driver:

There are four core keys to vibratory hammers: the first is processing accuracy, the second is heat treatment process, the third is accessory quality, and the fourth is assembly accuracy.

① The boring of the vibratory hammer box is processed by the new generation of Yasda high-precision constant temperature processing, which controls the concentricity, coplanarity and coaxiality errors of the shaft hole at the μ level, ensuring that when the pile hammer is running at high speed, there will be no adverse vibration, friction and power loss to the box. The overall movement is smoother, the work is more stable, and the frequent occurrence of high temperature is eliminated, which greatly increases the life span of the bearing and reduces the replacement frequency and cost of wearing parts.

② The box and gantry of the vibratory hammer are heat treated after welding and then fine-processed, so heat treatment is the most important part of the overall process.

Our heat treatment solution is: put the gantry and box into a high-temperature furnace and heat them to 800 degrees as a whole, keep them for 8 hours, then slowly cool them down, and take them out after 24 hours. This heat treatment can completely release the welding stress of the box and the gantry, while improving the performance of the material and avoiding frequent high temperature problems.

③The hydraulic motor uses the American Parker motor (most of the motors of the same level are LEDUC, Rexroth, and domestic Rexroth motors, and the price is generally only about half of Parker).

The bearings are SKF's VA405 bearings (the same level of bearings are VE series bearings, FAG bearings, and NSK bearings, and the price is only about 2/3 of the VA series).

The clamping cylinder adopts the largest diameter among the same type, which will provide better clamping force.

The shock-absorbing rubber is imported from South Korea, not domestically produced one.

The clip is made of one-piece precision casting.

④In modern manufacturing, the assembly accuracy of a machine is crucial for ensuring its overall performance and reliability. High assembly accuracy minimizes the risk of malfunctions and enhances the machine's efficiency, which is vital in meeting production demands. When components are assembled with precision, they fit together seamlessly, reducing wear and tear and extending the machine's lifespan. Moreover, accurate assembly contributes to consistent product quality, as even minor misalignments can lead to significant discrepancies in output.

The assembly accuracy of Zhonghe Machinery’s Vibration Hammer is high and guaranteed.

More Details:

Contact Details:

Kaiping Zhonghe Machinery is a big Manufacturer of Excavator Pile Driver Hammer

Welcome to contact for a big discount!

Whatsapp: wa.me/+8613822325403

Email: aria@excavatorboomarm.com

13822325403@163.com

Website link: www.excavatorlongarm.com

manufacturer excavatorlongarm longreachboomexcavator excavator excavation

|

|

Excavator Vibration Hammer Excavator Vibratory Pile Driver For Hitachi Images |